Phone: 780-484-3030 | Toll Free: 1-866-226-2414

Providing Excellent Customer Service Since 1960

How to Understand the Crankshaft’s Purpose in Industrial Engines

The crankshaft is the backbone of every industrial engine, converting the raw power of combustion into useful mechanical energy. This critical component, through its precise engineering and robust construction, determines engine performance, efficiency, and reliability. Understanding the crankshaft's purpose helps maintenance teams and engineers maximize engine output while preventing costly breakdowns.

Modern industrial engines require regular maintenance and specialized care to maintain optimal performance. Proper crankshaft maintenance involves multiple specialized processes, from basic inspections to complete engine rebuilding services. This article examines crankshaft types, manufacturing methods, maintenance requirements, and key factors that affect industrial engine operation and longevity.

The Fundamental Role of Crankshafts in Industrial Engines

At the heart of every industrial engine lies a masterpiece of mechanical engineering—the crankshaft. This vital component serves as the engine's working arm, transforming the intense forces of combustion into usable mechanical power.

Definition and basic function

The crankshaft is a sophisticated mechanical unit comprising several essential components:

- Main journals for engine block attachment

- Crankpins and cranks connected to connecting rods

- Counterweights for stability and balance

- Vibration dampers to reduce crank thrusts

- Flywheel mounting flange for power transfer

These components work in perfect harmony to ensure smooth engine operation. The crankshaft's design incorporates specialized features like hardened surfaces and tough cores to withstand the substantial loads involved in industrial applications.

Converting linear motion to rotational motion

The transformation of motion begins when the combustion process creates a downward force on the pistons. This linear motion travels through the connecting rods to the crankshaft's offset throws. The unique design of these throws, positioned away from the crankshaft's central axis, creates the leverage needed to convert this straight-line force into rotational energy.

The process relies on basic physics principles, where the leverage effect of force exerted on the crank journals twists the shaft. This mechanical advantage allows the crankshaft to maintain continuous rotation, pushing pistons up during compression and exhaust strokes while pulling air and fuel into cylinders during intake strokes.

Impact on engine performance

The crankshaft's influence on engine performance is profound and multifaceted. Its rotating mass, combined with the flywheel and harmonic balancer, creates crucial inertia and momentum that maintains consistent engine operation. This mechanical momentum ensures smooth power delivery and stable engine performance.

Counterweights are critical in maintaining stability and balance during high-speed operation. They help eliminate adverse reactions that could otherwise reduce engine speed, enabling the crankshaft to achieve higher RPMs safely. The precision-engineered journals provide secure attachment points to the engine block while allowing necessary rotation.

Surface hardening at bearing positions increases wear resistance, contributing to longevity and reliability. The continuous grain course in forged steel crankshafts enables superior torsion resistance, which is essential for handling the immense forces generated during industrial engine operation.

Types of Crankshafts Used in Industrial Applications

Industrial engines employ various crankshaft designs, each engineered to meet specific performance requirements and operational demands. Understanding these different types helps in selecting the proper configuration for particular applications.

Flat-plane crankshafts

Flat-plane crankshafts feature crank pins aligned in a single plane, positioned 180 degrees apart. This design offers several distinct advantages:

- Lighter weight due to smaller counterweights

- Higher revving capability

- Superior exhaust gas scavenging

- Compact design suitable for high-performance applications

However, these crankshafts experience more pronounced secondary vibrations, particularly at higher RPMs, requiring additional consideration in engine mounting and support systems.

Cross-plane crankshafts

Cross-plane designs position crank pins at 90-degree intervals, creating a distinctive cross pattern when viewed from the end. This configuration has become the standard for many industrial applications due to its:

- Excellent primary and secondary balance

- Smooth operation at various speeds

- Superior low-end torque delivery

- Enhanced durability under heavy loads

The trade-off is additional weight from larger counterweights and a more complex exhaust system design requirement.

Fully built vs. welded crankshafts

Fully Built Crankshafts

These components are assembled from separate pieces through shrink fitting, offering unique advantages for industrial applications. The construction involves joining journals, webs, and crank pins individually. This method allows for:

- Easy part replacement

- Simplified construction process

- Superior surface finish

- Better build quality through pre-assembly machining

Welded Crankshafts

Modern industrial engines increasingly utilize welded crankshafts, representing a significant advancement in manufacturing technology. These crankshafts are created using submerged arc welding with narrow gaps and low heat input. Key benefits include:

- Optimal combination of cost and strength

- Reduced weight and space requirements

- Higher natural frequency

- Improved bearing pressure distribution

- Enhanced fatigue resistance at weld points

The selection between these crankshaft types depends heavily on specific industrial applications, operating conditions, and maintenance requirements. Modern manufacturing techniques have remarkably enhanced the reliability and performance of welded crankshafts, making them increasingly popular in new industrial engine designs.

Manufacturing Processes and Materials for Industrial Crankshafts

Manufacturing excellence stands at the core of crankshaft reliability and performance in industrial engines. The selection of manufacturing processes and materials directly influences durability, strength, and operational efficiency.

Forging process

The forging process represents the gold standard in crankshaft manufacturing for high-performance industrial applications. This method begins with heating steel alloy bars to temperatures between 1950°F and 2250°F. Under immense hydraulic pressure, dies shape the heated material into the desired form, creating a robust internal grain structure.

Key advantages of forged crankshafts include:

- Superior strength-to-weight ratio

- Enhanced fatigue resistance

- Uniform grain flow pattern

- Excellent durability under high-stress

Casting method

Cast crankshafts emerge from pouring molten metal into precisely engineered molds. This traditional manufacturing approach produces components with tensile strengths ranging from 70,000 to 80,000 PSI for standard cast iron versions. Modern casting techniques incorporate nodular iron, pushing strength ratings to approximately 95,000 PSI.

The casting process requires careful control of the following:

- Mold preparation and design

- Material temperature management

- Cooling rate optimization

- Post-cast machining precision

Billet manufacturing

Billet manufacturing represents the pinnacle of crankshaft production technology. This process involves CNC machining a solid bar of high-grade alloy steel into the final product. The method allows for extreme precision and design flexibility, which is particularly beneficial for specialized industrial applications.

Material selection critically influences crankshaft performance and longevity. SAE-4340, a nickel-chrome-moly alloy, dominates high-performance applications due to its exceptional strength and fatigue properties. This material contains approximately 40 points of carbon and serves as the industry benchmark for ultra-high-strength alloys.

Modern manufacturing employs sophisticated refinement processes:

- Vacuum Induction Melting (VIM) for high-purity steel production

- Vacuum Arc Re-melting (VAR) for reduced dissolved gasses

- Precision heat treatment protocols

- Advanced surface hardening techniques

The evolution of materials science has introduced specialized variants like EN-30B and 32-CrMoV-13, particularly suited for extreme-duty applications. These materials undergo rigorous quality control processes, including magnaflux testing and precise chemical composition verification.

For industrial engine applications, material selection balances several factors:

- Operating environment demands

- Load-bearing requirements

- Cost considerations

- Maintenance intervals

- Performance specifications

The manufacturing process culminates in various surface treatments and quality control measures, ensuring each crankshaft meets stringent industrial standards. Modern facilities employ advanced testing methods, including ultrasonic inspection and precision balancing, to verify component integrity before deployment in industrial engines.

Maintenance and Inspection of Industrial Crankshafts

Maintaining the operational integrity of industrial engines demands a comprehensive understanding of crankshaft care and inspection protocols. Regular maintenance extends service life and ensures optimal performance under demanding conditions.

Signs of wear and tear

Early detection of crankshaft issues prevents catastrophic engine failures. Key indicators that signal potential problems include:

- Engine knocking sounds during operation

- Decreased oil pressure readings

- Excessive vibration during acceleration

- Reduced fuel efficiency

- Irregular engine performance

- Visible bearing marks or surface pitting

The most critical areas for wear examination are the transition filets between crank arms and journals, where transverse cracks commonly develop. Oil holes require particular attention, often showing early signs of axial cracking along sharp edges.

Importance of regular inspections

Professional inspection protocols incorporate multiple examination methods to ensure a comprehensive evaluation. Magnetic particle inspection (MPI) is the industry gold standard for detecting surface and near-surface defects in ferromagnetic materials.

Regular inspection schedules should account for:

- Operating environment conditions

- Load patterns and duty cycles

- Historical maintenance data

- Manufacturer recommendations

- Industry-specific requirements

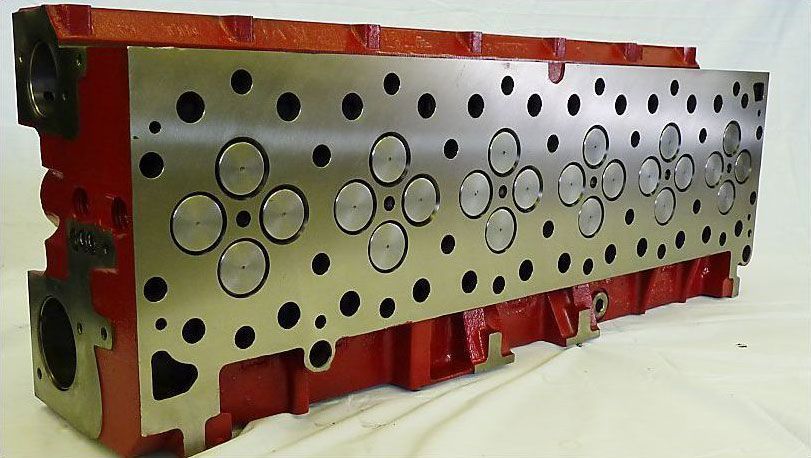

Reconditioning processes

When wear exceeds acceptable tolerances, various reconditioning methods can restore crankshaft functionality. The process begins with a comprehensive failure assessment to determine the appropriate repair strategy.

The standard reconditioning sequence includes:

1 - Initial Assessment

- Visual inspection of crank casting

- Magnetic particle examination

- Dimensional verification

- Surface finish evaluation

2 - Corrective Procedures

- Journal grinding to remove wear

- Surface polishing using specialized equipment

- Superfinishing with carborundum stone

- Heat treatment for hardness restoration

3 - Quality Verification

- Post-repair dimensional checking

- Surface finish measurement

- Geometric tolerance verification

- Final magnetic particle inspection

Modern crankshaft reconditioning employs sophisticated equipment, such as micro-polishers with rigid polishing systems. These machines utilize solid abrasive tape wrapped around journals, applying equal pressure through specialized shoes to achieve optimal surface finish.

For severe cases requiring material removal, undersized bearings compensate for reduced journal dimensions. This process demands precise measurement and careful selection of replacement components to maintain proper operating clearances.

Heat treatment services are crucial in reconditioning, particularly when addressing stress-induced issues. The process involves:

- Controlled heating cycles

- Precise soaking periods

- Regulated cooling using ceramic blankets

- Careful monitoring of material properties

Peen straightening techniques address stress-induced bending, utilizing specialized hammers to restore proper alignment. This process requires extensive expertise to avoid creating additional stress points while correcting existing deformation.

The success of reconditioning depends heavily on maintaining proper geometric tolerances and surface finishes. Modern engines, especially those using thinner viscosity oils, demand extremely smooth journal finishes, often requiring 6 Ra or less. This precision ensures optimal bearing performance and extended service life.

Post-reconditioning procedures include carefully labeling any undersized journals, typically marked on the forward face of the front counterweight. This documentation ensures proper matching with appropriate bearing sizes during future maintenance operations.

Conclusion

Industrial crankshafts are masterpieces of engineering that combine sophisticated design principles with advanced manufacturing techniques. These vital components transform linear piston movement into rotational force through precise engineering, whether manufactured through forging, casting, or modern billet processes. From traditional cast iron to advanced steel alloys, material choices directly impact performance capabilities and service life, making proper selection crucial for specific industrial applications.

Successful industrial engine operation depends on regular crankshaft maintenance and professional inspection protocols. Careful attention to wear patterns and timely reconditioning processes ensure optimal performance and prevent costly failures. Modern maintenance techniques, advanced inspection methods, and proper reconditioning procedures work together to maximize engine reliability and operational efficiency, protecting valuable industrial assets and maintaining consistent power delivery for critical applications.

The Weldangrind Group

10323 174 St NW

Edmonton, AB

T5S 1H1

Phone: 780-484-3030

Toll Free:

1-866-226-2414

Email:

info@wgltd.ca

Fax:

780-484-4242

Edmonton's best engine machine shop.

Diesel Component Rebuilders (DCR)

Phone:

780-484-3030

Toll Free:

1-866-226-2414

Fax:

780-484-4242

DK MACHINE

Phone:

780-484-3030

Toll Free:

1-866-226-2414

Fax:

780-484-4242

MENU

HOURS

Mon-Fri: 8:00 AM – 4:30 PM

*Long Weekend Summer Hours: Please note that our shop will be closed at 2:30pm Fridays and will resume regular business hours on Tuesday, from May to September.